section-48793e5

PRODUCTS

section-456931a

Convincing features

- large volumes with OD/ID = 1.66

- no limitation on the number of side feeders

- quick change option

- simple design: electronics in the machine frame

- 4 instead of 2 heating cartridges per barrel

- high temperature applications possible

Convincing features

- flexible operation thanks to tie rods as barrel connections

- high torque for torque-limited formulations

- reference machine for countless institutes and research facilities

- highly flexible LSA die heads with filters

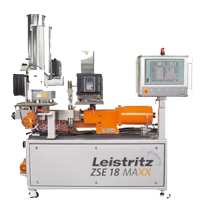

Convincing features

- ease of cleaning

- high torque density

- maXX cooling with doubled in and outflow of the coolant

- easy operation

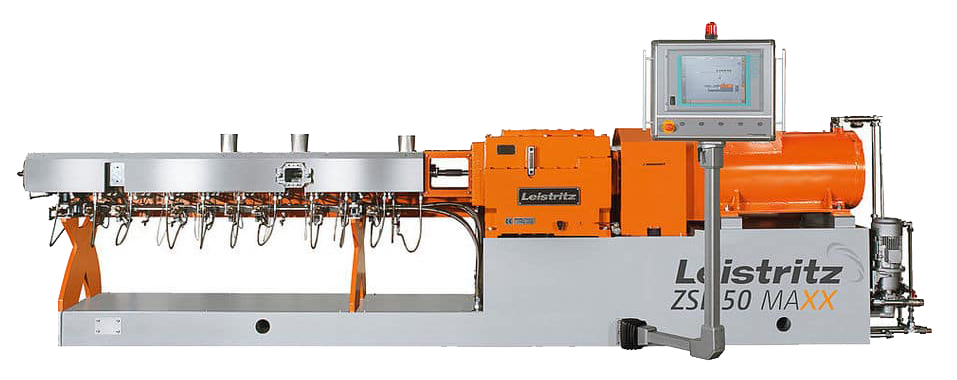

Convincing features

- very wide process window

- high torque

- efficiency-optimized lubrication system in the gears

- water-cooled three-phase motor

- tidy design

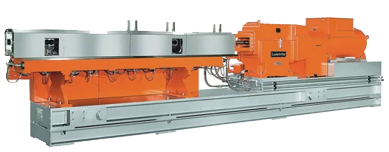

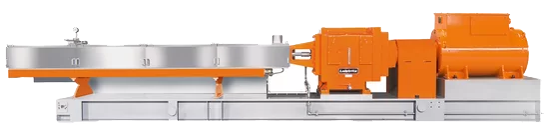

Convincing features

- solid machine base - guaranteed vibration-free

- high torque

- water-cooled three-phase motor

- modular screw design with maXXshaft spline profile

Convincing features

- very wide process window

- high torque

- oil supply at the machine frame

- high-tech gearbox - low-maintenance

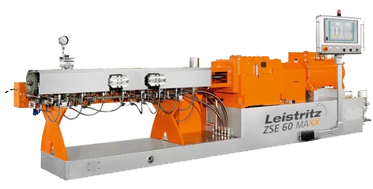

Convincing features

- high torque

- water-cooled three-phase motor

- optimized barrel cooling

Convincing features

- optimum volume-torque ratio

- water-cooled three-phase motor

- noise-optimized maXXtorque gearbox with extremely high power density

Convincing features

- modular screw and barrel system

- machine concept on platform design

- neat design

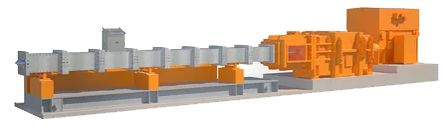

Convincing featuresefficient machine for high throughput very high torque density integration of all process units into a single control unit

Convincing features

- optimum homogenization with efficient energy input

- modular drive system with high quality gears and motors

- high productivity

- barrel connection using clamping flanges

Convincing features

- variable-speed drive

- very broad process window

- best product quality, even for processes with a high energy demand

section-a70e7b5

VIDEOS

section-9dc3043

Compounding with twin screw extruders

Compounding with twin screw extruders

Masterbatch production with twin screw extruders

Lab Extrusion with twin screw extruders

Direct Extrusion with twin screw extruders

Film Extrusion with twin screw extruders

Pipe Extrusion with twin screw extruders

Production of Highly Filled Compounds

Controls for twin screw extrusion lines

Leistritz Online Dehnrheometer

section-0dc5548

CONTACT US

FOR TRIAL RUN , QUOTATION, SPARE PARTS

FOR TRIAL RUN , QUOTATION, SPARE PARTS

Office 028 3811 0138

Tong 936 71 03 05

Jake@dhvietnam.com.vn